Dongguan Inflight Electronic Co., Ltd.

About qualification

| 1995 | UL CSA |

|---|---|

| 2002 | ISO9001 VDE |

| 2004 | BABT CCC |

| 2007 | ISO14001 : 2004 |

| 2010 | ISO9001 : 2008 |

| 2013 | TS1649 (SMT) |

| 2015 | QHSAS18001 |

| 2015 | QS |

| 2017 | Disney |

| ISO9001 : 2015 | |

| 2020 | ISO14001 : 2015 |

| Apple/MFI | |

| 2019 | ISO45001 : 2018 |

Vision

We aim to increase corporate value through our strong commitment to the efficiency, transparency, and legitimacy of our management practices.Company Overview

| Company Name | Dongguan Inflight Electronic Co., Ltd. |

|---|---|

| Location | No.255 Changdong Road, Chanping Town, Dongguan, Guangdong Province, China |

| TEL | +86-769-8339-2291 |

| FAX | +86-769-8339-2224 |

| Company Email Address | iida@dgiida.com |

| Founded | March 1, 1993 |

| Capital | 221,900,000 HKD (100% investment by Inflight Precision Industries, Ltd.) |

| Number of Employees | 170 employees (as of April 2024) |

| Business | Touch panel bonding, assembly of consumer services and industrial equipment |

| Company Introduction | Dongguan Inflight Electronic leverages its manufacturing facilities in China to produce cost-effective products while maintaining a high level of quality. The company caters to the needs of customers by combining its functions as both a manufacturer and a trading company. |

Key Features

| Global Activities | Uses Hong Kong as a trading hub to source materials from all over the world |

|---|---|

| Manufacturing | Ensures high quality production and punctual delivery of orders |

| Customs | Recognized with AEO Advanced Certification |

| Equipment | Sources cost-effective equipment through local procurement and in-house production |

| System | ERP-based production management system adapted to production fluctuations |

Clean Room

| Equipped with a 5,000 sqm clean room | Class: ISO 14644-1 Class 7 (Less than 2,930 particles equal or greater than 5 micron per cubic meter) |

|---|---|

| Clean Benches | Class 6 (Less than 290 particles equal or greater than 5 micron per cubic meter) |

| Manufactured Goods | LCDs and touch panels |

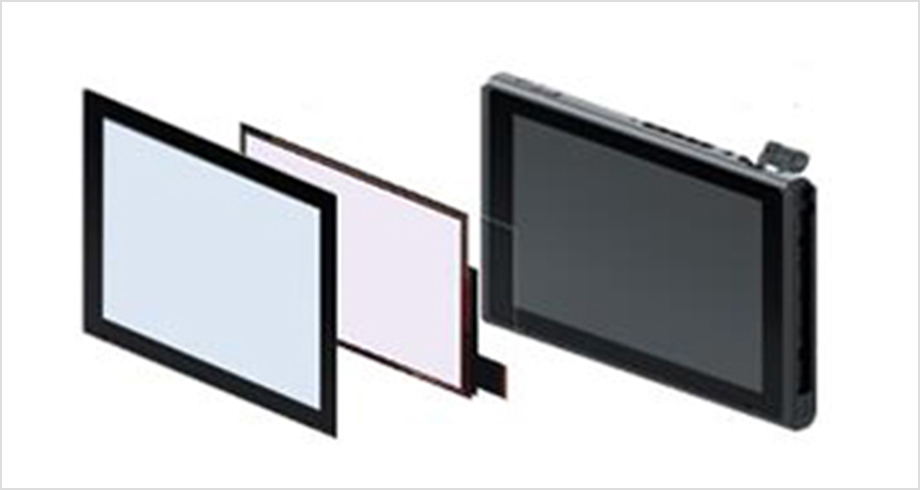

Touch panel bonding, assembly of consumer services and industrial equipment

Our China factory has a 5,000 sqm clean room. By expanding the bonding technology we cultivated in the cellphone business, we have increased production of panels for game consoles and barcode readers. The factory is also tackling upsizing its bonding devices for automotive applications to meet the demand for glass automotive panels.Fully automatic ACF crimping machine

Game consoles

- 36 million units delivered since August 2016 with production ongoing

- Highly efficient production line manufacturing the same kind of panels for cellphones and barcode readers

Automotive panel bonding

- Panel sizes corresponding to 2020 production targets

- Installed large-scale bonding devices due to the urgent need to improve workability given the large size and weight of panels under production development

Assembly and processing of precision machines

“The factory handles the assembly of products that require precision and accuracy, such as cellphones. (Products include cellphones, automobile communications terminals, and measuring instruments)”

Advanced analysis technology and production engineering

Production flow and analysis technology

Accurate and fast analysis technology through the optimal use of various precision analytical instruments Coordinate Measuring Machines

Coordinate Measuring Machines RoHs Testing Equipment

RoHs Testing Equipment FTIR Spectrometer

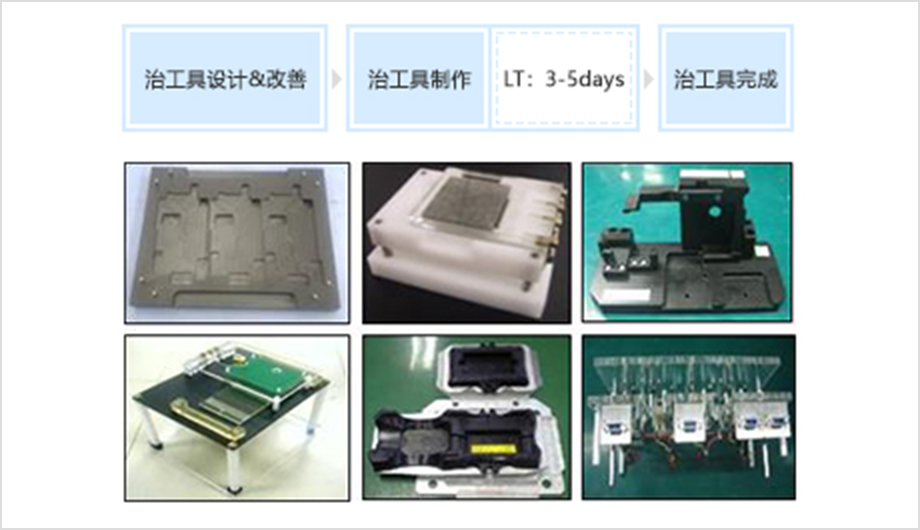

FTIR SpectrometerIn-house production of manufacturing equipment, jigs, and tools

CNC Cutting Machine – 3D Cutting Machine

CNC Cutting Machine – 3D Cutting Machine Jigs and tools / Test boards

Jigs and tools / Test boards Roller-type Mounting Machine

Roller-type Mounting Machine Large-size Vacuum Mounting Machine

Large-size Vacuum Mounting Machine